1. High reliability: The wiring harness of this Jamma arcade game machine adopts high-quality materials to ensure long-term stable operation. Even under long-term continuous use, the electrical connection can remain highly reliable, avoiding game interruptions due to poor contact or failure, and adapting to heavy operating environments.

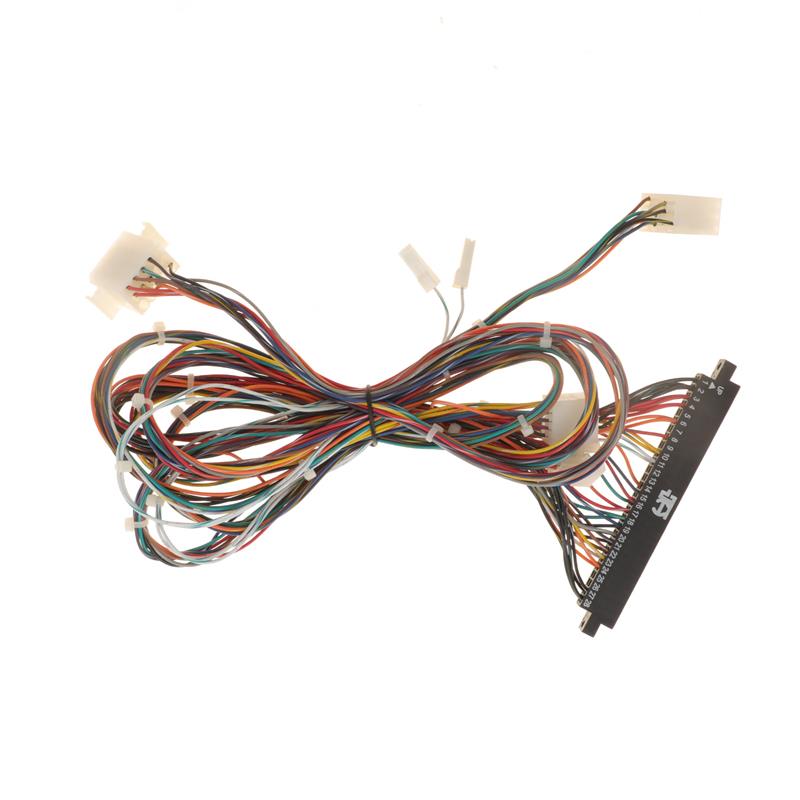

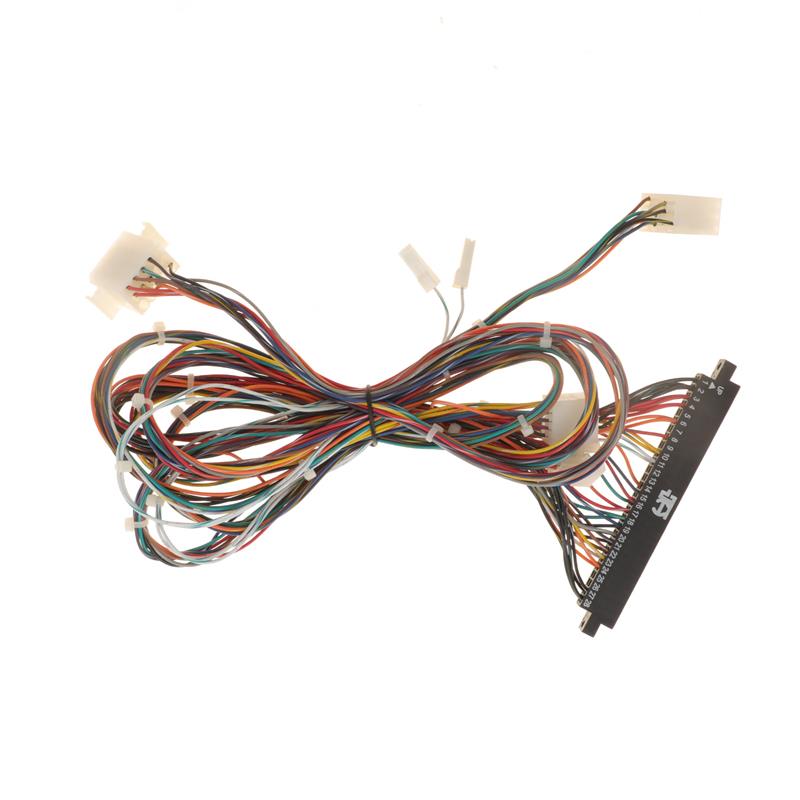

2. Complex multi-core design: The wiring harness contains multiple wires, which can simultaneously connect various devices and functional modules, such as display screens, buttons, lights, payment systems, and power modules. Whether it is traditional mechanical control or modern electronic modules, it can ensure smooth electrical connections and meet the needs of arcade game machines for complex layouts.

3. Durability and wear resistance: The wiring harness adopts durable materials with excellent wear and tear resistance, which can cope with the frequent movement and friction inside the arcade game machine, ensuring that it is not easy to be damaged during long-term use, thereby reducing the frequency and cost of maintenance.

4. Anti-interference: In order to ensure the accuracy of signal transmission, this wiring harness has excellent anti-electromagnetic interference (EMI) ability, which can effectively resist the interference of external electromagnetic waves on the signal, and ensure the stable operation and precise response of the game equipment.

5. Flexibility and ease of installation: The wiring harness design takes into account the complex internal layout of the arcade game machine and has sufficient flexibility to easily adapt to different models and sizes of game machines. The installation is convenient and quick, reducing the difficulty of operation for the installer.

6. Flame retardancy: In order to ensure safety, the wiring harness uses flame retardant materials, which can effectively prevent fires caused by overheating or electrical failures, especially in high-load working environments, and can maximize the safety of operators and equipment.

7. Standardization and customization: This wiring harness supports standardization and customization services, and can design exclusive connectors and interfaces according to the brands and models of different arcade game machines to meet the personalized needs of different customers.

8. Separation of power cord and signal line: In order to avoid mutual interference between power cord and signal line, the wiring harness is specially designed with a separate layout of power cord and signal line to ensure the stability of power supply and the integrity of signal, which greatly improves the reliability and performance of the system.

These features make Jamma Arcade Game Machine Wiring Harness a reliable, efficient and safe solution, which is widely used in various types of arcade game machines to meet users' needs for high-quality electrical connections.